About Us

Vijaya Lakshmi Forge and Stamping An ISO 9001 : 2015 Certified Company is a Chennai based company with specialization in the forging of Carbon, Alloy, and Stainless Steel. The company was established by Mr. A. Kumar in the 1988. Today the company is a well known name for Precision, Perfection and Performance.

Presently the company is being lead by Mr. A. Kumar is the managing director of the company. It is because of his hard work, leadership, understanding of customer’s requirements and undelivered efforts and quality consciousness that the company is marking towards new business and is continuously increasing its market share

The company is having all in-house facilities to support its operations with modern machines. The unit is equipped with latest techniques and Experienced staff to cater the needs of its customers. The company is having testing Lab with to assure the quality of its products. Products inspection and testing is carried out to meet requirements of the customers

In-house Facility

Outsource Facility

Product Range

Gear intermediate

Customer : SFL Hosur

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Keyway sprocket

Customer : TIDC

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Sprocket

Customer : TIDC

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Forged Link

Customer : TIDC

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Connecting Pin

Customer : TIDC

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Clevis

Customer : Wheels India

3 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Trunnion

Customer : Wheels India

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Hydraulic cylinder cap

Customer : Wheels India

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

SHC-991 ROD EYE

Customer : Wheels India

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Planetary gear

Customer : Bonfiglioli

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Flange Shaft

Customer : Bonfiglioli

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Body forge

Customer : Flowserve Audco

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Flange Shaft

Customer : Bonfiglioli

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Body forge

Customer : Flowserve Audco

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Bolts

Customer : SFL Padi

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

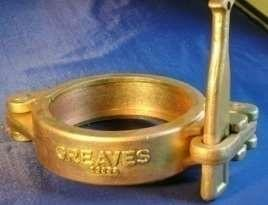

DN 125 COUPLING ASSY

Customer : Greaves limited

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Fork Lever

Customer : Unimec Industries

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

SOCKET JOINT

Customer : NEW TECH INDUSTRIES

2 Stage Hot forging

Parts forged at high Temperature 1200 °C.

Clients

Contact us

Mr. R.Ganesh

- +91 - 98404 07255

Mon - Fri, 9am - 5pm

vijlakforging@gmail.com

Visit

SP 48, 3rd main Road, Ambattur Industrial Estate, Chennai – 600 058

Registered Office

SP 48, 3rd main Road, Ambattur Industrial Estate, Chennai – 600 058

Plant I

18,2nd street, Tass Industrial Estate, Ambattur,Chennai – 600 098

Plant II

G50,Sidco Industrial Estate, Kokkalur,Chennai – 602 003

© All rights Reserved. Vijaya Lakshmi Forge and Stamping .